Base layer drying time can be considered one of the principal determinants when choosing base layer clothing. One of the primary advantages of next to skin garments is their moisture management ability, as such, the base layer drying time is of great importance when selecting these products. During our lengthy base layer evaluation between natural and synthetic fabrics, we assessed and tested the drying capabilities of both polyester and merino wool.

Base layer drying time in real-world field conditions

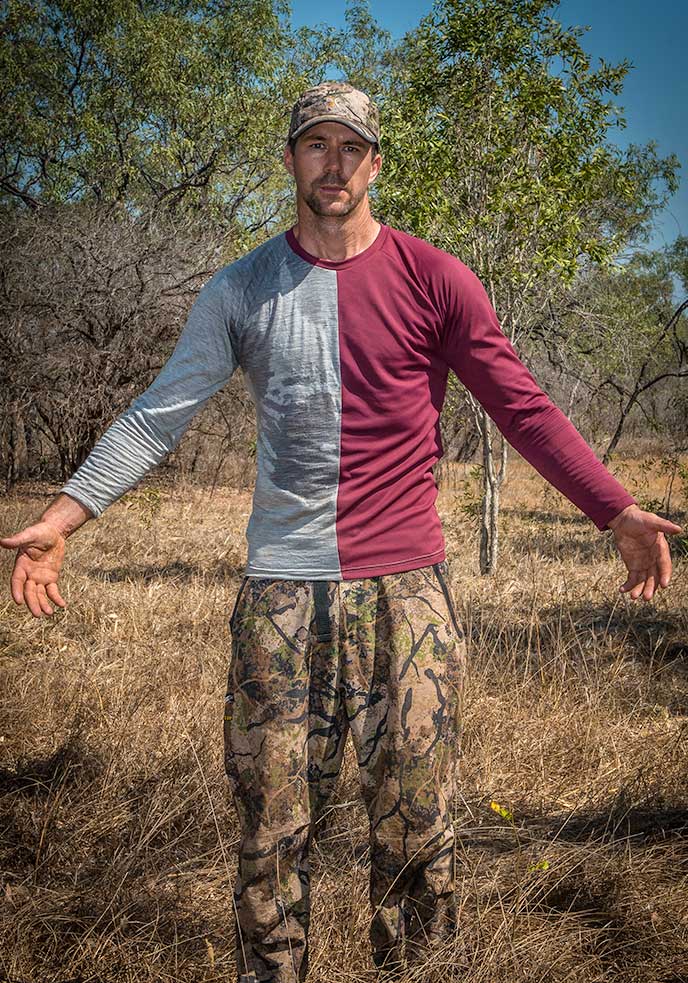

While researching the advantages and disadvantages of merino wool and polyester base layer fabrics, we undertook wear trials using prototype merino wool and polyester harlequin half tops. After months of field use, feedback from field testers of the prototype base layer drying time was in favour of the polyester side of the prototype. While most users observed the polyester fabric dried faster, opinions were divided on which of the fabrics were preferred for their moisture management ability.

Some users reported they preferred merino wool for its ability to feel warmer in cold circumstances even when wet, where the polyester felt cooler in these same conditions. Others liked the way polyester reached a dry state quicker. As expected, feedback was very subjective as comfort perceptions to thermal differences can vary with individuals. It was for this reason that we wanted to cross-examine the subjective field reports with objective laboratory tests to try and discover a common ground.

Active hunting can result in high build up of perspiration. Base layer drying time can be an important consideration for next to skin comfort.

When wearing a backpack, the pack harness and straps can often lead to saturated contact points. Employing a fast drying base layer can improve comfort levels.

Base layer moisture management laboratory analysis

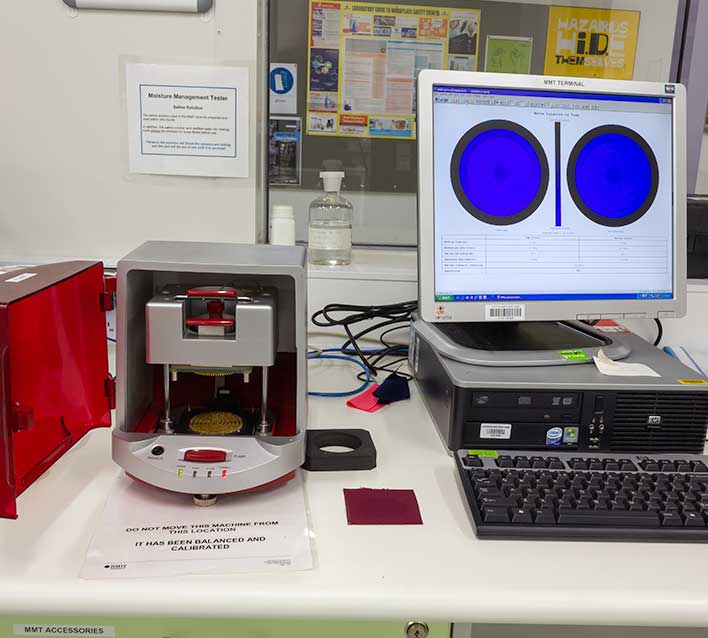

Moisture management properties of the sampled merino wool and polyester fabrics were tested and evaluated by using the Moisture Management Tester according to the American Association of Textile Chemists and Colourists (AATCC) Test Method 195–2009.

The Moisture Management Tester is a sophisticated instrument that evaluates absorption properties by measuring changes in electrical conductivity. Fabric specimens are placed within the top and bottom sensors of the device, the top or inner surface of the fabric represent the surface closest to the skin of the human body; while the bottom or outer surface can be considered the fabric facing the environment. Samples can be evaluated for their liquid moisture management properties through various indices, however, these values can be difficult to interpret. To address this, the indices can be converted from a value to rank based on a five-grade scale (1–5). The five grades of indices represent; 1 – poor, 2 – fair, 3 – good, 4 – very good, 5 – excellent.

The Atlas Moisture Measurement Tester is used to measure the dynamic liquid transport properties of knitted and woven fabrics. This state of the art technology of international standard is ideal for conducting sophisticated testing for product quality control and diagnostic investigation.

Base layer moisture management laboratory results

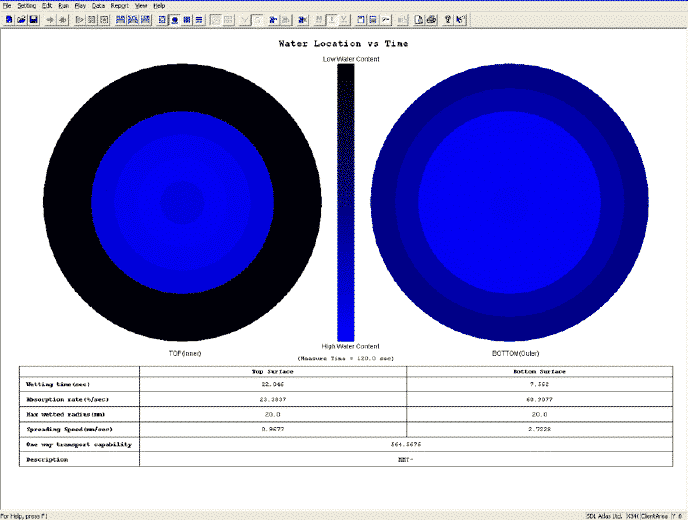

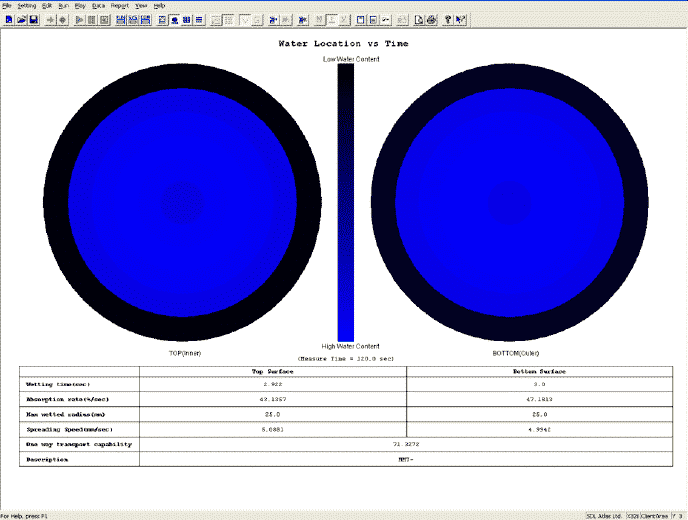

Results of the moisture management tests indicate that the sample merino wool fabric outperforms the sample polyester fabric with an overall moisture management score of ‘very good’ (4 out of 5). The polyester fabric came in at a close second place attaining a reasonable rating of ‘good’ (3 out of 5). Both of these tested fabrics can be considered a good choice for next to skin base layer fabric.

Map of water location results from the Atlas Moisture Management Tester, this is one of the many sophisticated moisture management results this instrument can produce. These diagrams represent the spreading capability of a fabric to transport moisture from the skin surface (left circle) to the outer side of the fabric (right circle). Black colour represents low water content, while blue represents high water content.

The first image displays the results from the test merino wool fabric, while the second represents the polyester fabric. In our series of tests, the merino wool outperformed the polyester attaining a higher moisture management score.

Base layer drying time laboratory analysis

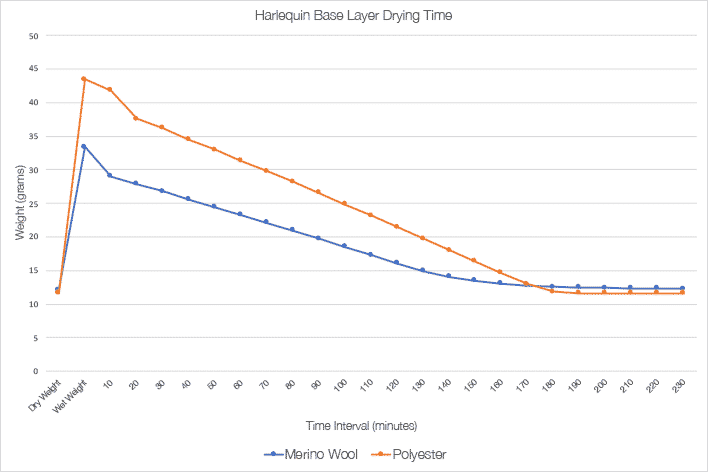

To determine the saturated base layer drying time of the test merino wool and polyester fabric, samples were first cut to 30x30cm dimensions, with the dry weight of each sample recorded. The average maximum absorption capacity value (C) obtained during the demand wettability test was used as the amount of water added to the test sample. Following saturation of the fabric, the wet weight was defined, and the sample then allowed to line dry in an atmosphere of 21C +/- 1C with a Relative Humidity of approximately 35%. Timing commenced at this point with the samples being weighed and recorded at 10-minute intervals. This procedure was continued until fabrics returned to their original tare weight, or weight was constant for successive readings.

Base layer drying time laboratory analysis – Results

Although lighter in weight at 130gsm, the test polyester fabric was, in fact, thicker; being 0.49mm as opposed to the test merino wool having a fabric thickness of 0.30mm and a weight of 135gsm. Upon fabric saturation, this has meant that the polyester fabric had absorbed approximately 3.74 times its dry weight in moisture with 31.87 grams of water absorbed; while the merino wool had absorbed 2.76 times its dry weight at 21.33 grams. Remarkably the polyester was still able to dry faster despite the disadvantage of absorbing more moisture, attaining its dry weight in a time of 190 minutes, 20 minutes ahead of the merino fabric that had taken 210 minutes to reach its dry weight.

This experiment merely demonstrates the base layer drying time while on a line, wearing fabric directly against human skin may likely produce different results. Feedback from our wear trial field testers was consistent that the polyester fabric dried faster in real-world conditions.

Although the test merino fabric was slightly lighter than the test merino wool, the fabric was actually thicker being 0.49mm as opposed to the merino wool measuring 0.30mm. This resulted in the polyester fabric absorbing more water during the line dry test.

Having started with the disadvantage of absorbing more moisture, the polyester fabric was still able to dry faster than the merino during the line dry test.

Conclusion

While base layer drying time favours synthetic fabrics such as polyester, the inherent capabilities of merino wool fibres can give this fabric advantages in other areas of moisture management. As such, a polyester fabric can be considered a wise choice when base layer drying time is of critical importance, such as very wet and cold environments; potentially negating the evaporative cooling effect of wet or damp clothing directly against the skin.